Mahindra Manufacturing Logistics Supply Chain OptimizationManufacturing Design & Implementation

About the Organization | Mahindra

Mahindra is a 20.7 billion USD multinational group, with a presence in more than 100 countries and employing over 240,000 people. Mahindra’s portfolio spans across a wide spectrum of product portfolio and services. Mahindra is one of the largest vehicle manufacturers by production in India and the largest manufacturer of Tractors in the world.

Project Mahindra | Business Case

This Supply Chain project is in the Mahindra Commercial Trucks division where a multi fold growth is forecasted and the current supply chain has to be optimized in terms of space, flow, resources and systems. The Business case of the project driven by Hesol Consulting is to optimize the Manufacturing Logistics Supply Chain in the Commercial Truck Building Facility, India.

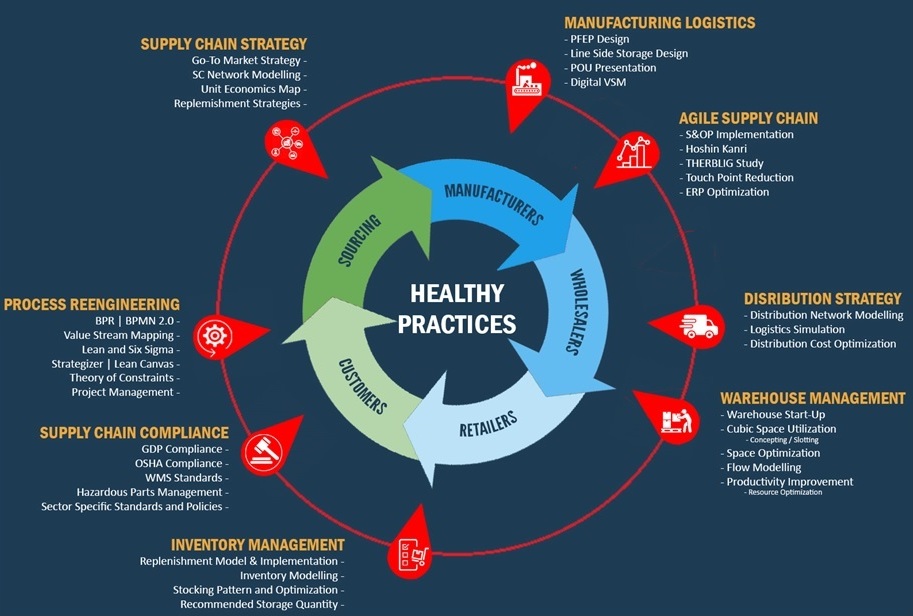

In the overall Hesol’s Supply chain services portfolio (shown below) – Manufacturing logistics, Warehouse management and Inventory management are the core focus areas in Project Mahindra.

challenge

Scope of Work

Basis the discussion with the client and the initial data points the scope of work is formulated. The Scope of work includes –

- Commercial Truck Building Facility Inventory Optimization – right sizing, recommended storage quantity and stocking patterns

- Central Tyre Storage Facility Inventory Optimization – right sizing, recommended storage quantity and stocking patterns

- Supply Chain Optimization at Commercial Truck Building Facility which includes but not limited to –

- Improve Space utilization

- Enhance Storage efficiency through design

- Efficient product flow from Dock till Point of use

- Right Stocking Pattern across Supply Chain

- Manufacturing Logistics Optimization at Commercial Truck Assembly Facility

- Warehouse Optimization at Central Warehouse for Tyre Storage which includes but not limited to –

- Right Storage Design

- Efficient & Improved Flow and Handling

- Storage space reduction by Right Sizing

- Container design for Storage and POU Delivery (Line side feeding)

- Improve cubic space utilization

- Right Stocking Pattern across Supply Chain

Tools & Techniques used

- Facility Layout Capacity Map

- Value Stream Map

- Space Modelling

- Slotting Technique

- DFEP – Design for Every Part

- Traffic Study

- Congestion Analysis

- Process Flow Diagram

- Spaghetti Diagram

solution

Game Plan for Mahindra

The game plan for Mahindra is 4 Folds:

(1) Inventory analysis across the supply chain and Inventory fixes to set right the stocking pattern, quantities and the overall availability. The objective is right sizing of inventory without impacting the service fills

(2) Process standardization – this includes validation of plan for every part (PFEP) and use that as base for the design of every part; this also includes right put-away and picking methodologies, line feeding strategies and point of use (POU) to suit the operations

(3) Space Optimization – this includes simulation and modelling to come up with the right storage design based on the recommended storage quantities

(4) Material Flow & Handling – parts analysis by velocity and slotting based on the point of use thereby the parts flow from dock to point of use is streamlined and evaluating and designing the right handling solutions.

The game plan applies for the Commercial Truck building (assembly) facility as well as the Central Tyre Storage (warehouse).

Project Execution

The project execution is as per the game plan. Some of the Key highlights of the manufacturing logistics solution are –

Validation of PFEP – the validation is done by mapping on floor by value stream, by the existing plan for every part and by the logistics POU delivery data. Once the PFEP is validated the design for every part (DFEP) is done basis that.

Detailed multi fold Inventory Analysis by the lead time, cycle times, sales, demand variations, lead time variations, stocking points, put-away, replenishment and delivery at POU methodologies. Basis the analysis the inventory inefficiencies are listed and actions are set.

Parts characteristics are documented and Concepting / slotting runs are done to finalize the storage design and structure.

Layout based Value Stream Mapping is done for the entire facility and the key parameters like the capacities, days of stock and the replenishment strategies are documented in the value stream map.

Parts categories are mapped by each zone according to the delivery at POU and Zone wise Capacities are created well by designing storages utilizing the cubic space.

Efficient replenishment strategies specific to the parts characteristics and usage pattern and delivery at POU; Zone wise strategies part of solution are Supermarket design, 2-Bin Replenishment, Let Down Concept, Pick path sequencing and Heavy parts dense stack zones.

results

Feedback from Mahindra

“We (Mahindra) had great experience working with you (Hesol Consulting). Your passion, dedication, approach on logistics planning is appreciable. Your low cost and transparent business model will take you long ahead”.

- 120% Improvement in Space Utilization (Capacity) in Passenger Tyre Storage (Central Warehouse)

- 64.2% Improvement in Space Utilization (Capacity) in Commercial Tyre Storage (Central Warehouse)

- 23% Reduction in Handling (Touch Points) throughout the Manufacturing logistics supply chain

- 2X Improvement (Double Capacity) at Manufacturing warehouse and stocking zones at the 2,50,000 Square feet

- Truck building facility

- 16.5% Channel Inventory Reduction at the Truck Building Supply Chain

- 70+% Parts with excess stock, identified by calculated Recommended Storage Quantities which would result at huge Inventory Savings

- Efficient replenishment strategies specific to the parts characteristics and usage pattern and delivery at POU; Zone wise strategies part of solution are Supermarket design, 2-Bin Replenishment, Let Down Concept, Pick path sequencing and Heavy parts dense stack zones.